What are MIL-DTL-38999 Connectors?

What is a 38999 Connector?

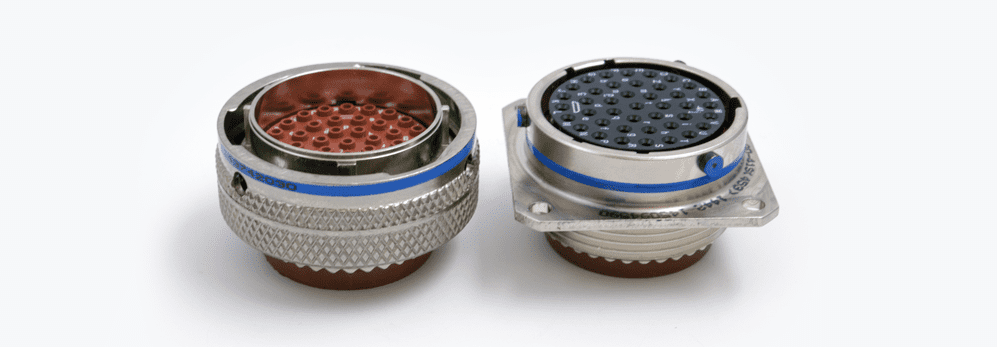

38999 connectors are a subminiature high-speed circular connector used for military, aerospace, and other rugged, high-reliability applications. They are also known as MIL-DTL-38999 and D38999 connectors. This connectors are ruggedized and environmentally resistant and feature removable crimp or fixed solder contacts. The 38999 is one of the best-selling connectors in history.

The evolution of the 38999 connector began in the 1930s, when the U.S. Department of Defense determined a need for lightweight connectivity in tactical and aeronautical designs. The Douglas Aircraft Company, Boeing, and the Vega Company collaborated with the government between World Wars I and II to develop an electrical connector to support military aircraft. Douglas contracted with Cannon (now ITT Cannon) to create the ANSI 9534 standard circular connector, a precursor to MIL-C-5015 (subsequently MIL-DTL-5015), for use in its Douglas DC transport aircraft. However, limitations with that product, including inefficient use of panel space and only one keying option, led to continued development in the 1950s and 1960s. In the 1970s, the rise of increasingly complex electronic equipment created a need for greater signal capacity. This led to the MIL-C-38999, a smaller, high-density circular connector that enables high-speed data transmission. It includes up to 128 contacts with a variety of keying options and shell sizes. Today, the connector known as the MIL-DTL-38999 has four unique sub-types. They are available in shell sizes ranging from #9 to #25, with up to 128 pins in more than 50 QPL-approved insert arrangements.

The four types of 38999 connectors (image courtesy of Federal Connectors).

- Series 1 Bayonet 38999s are used where a quick-disconnect coupling system is required for blind mating or difficult-to-access areas. They are scoop-proof to protect the contacts. This connector has high vibration properties and is suitable for high-wind and moisture environments.

- Series II Low-Profile Bayonet 38999s are used in applications where size and weight considerations make a low-profile connector desirable, including aviation, communications, Test & Measurement, and medical applications. These non-scoop-proof, high-density connectors feature a shorter pin length than the other versions. They accept insert arrangements that accommodate pin sizes ranging from #12 to #22D. (These connectors were originally released as the Bendix JT “Pancake” before Bendix was acquired by Amphenol.)

- Series III Stub-ACME Thread 38999s are coupled using a triple-start threaded screw to enable fast mating and secure connections for high-vibration and high-temperature applications. This version is scoop-proof. They are the most prevalent military and aerospace connectors in use. They meet Boeing specification BACC63 and Airbus specification EN3645.

- Series IV 38999s feature a 90° quarter-turn “breech-lock” mate with visual, tactile, and audible engagement confirmation. They are used in missile applications and other military and aerospace applications where robust mating and extreme resistance to vibration and shock is required.The insert arrangements are provided in MIL-STD-1560.

Design Notes

- Standards The MIL-DTL-38999, formerly known as MIL-C-38999, is designed to meet the stringent MIL-Spec requirements set forth by the U.S. Department of Defense. It is a Qualified Parts List (QPL) connector.

- Coupling Options The 38999 connector series is available in bayonet, breech, and threaded options and is suitable for blind-mate applications.

- Keying Options Six distinct keying options are available for each shell size.

- Customization This is a highly configurable connector and one of the most popular connector series for value-added-connector distributors such as Interstate Connecting Components (ICC), PEI-Genesis, and TTI Inc. to assemble for customers.

- Accessories Connector savers, protective plug and receptacle covers, jam nuts, and storage receptacles are available for this commonly used connector type.

- Mating Cycles From 500 to 1,500 mating cycles, depending on series and manufacturer.

- Materials Originally designed as aluminum connectors, the MIL-DTL-38999 is now also available in nickel, composite, stainless steel, and hermetic options. Finish options include a variety of space-grade, electroless nickel, black zinc nickel, nickel PTFE, olive drab cadmium, and passivated stainless steel.

- Ruggedization MIL-DTL-38999 connectors are highly rugged and designed to be resistant to shock, vibration, harsh environments, and temperature extremes (most versions are rated -65 °C to +200 °C), and hermetic sealing prevents ingress of moisture and debris.

- Pronunciation The MIL-DTL-38999 is known as the “38-triple-nine.”

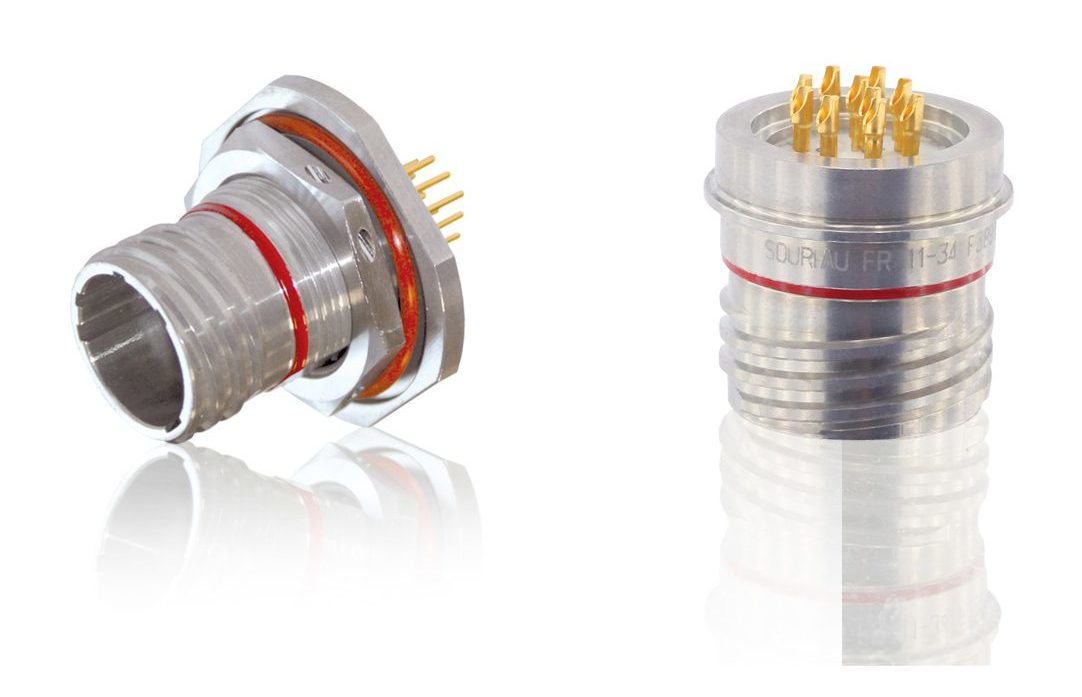

Glenair’s SuperNine Hermetic is a glass-sealed Series III 38999 connector with removable crimp contacts.

Markets, Sectors, and Applications

Military and commercial aircraft, weapons systems, armored vehicles, ships, oil & gas, instrumentation, heavy transportation equipment, medical equipment, and other high-performance, harsh-environment applications. A space-grade variation, D38999, serves spacecraft, satellites, and rocket launchers.

Amphenol’s MIL-DTL-38999 Series II and commercial JT series connectors are available in nine shell sizes with EMI shielding and error-proof positioning. This product is also qualified to the MIL-DTL-27599 specification for Series II connectors.

Suppliers

Amphenol Aerospace, ITT Cannon, Glenair, TE Connectivity, and Souriau (Eaton) (available from Allied Electronics & Automation, Mouser Electronics, TTI Inc., and other distributors).

Related Products

- MIL-DTL-5015

- D38999

- MIL-STD 1560

- MIL-STD-1760

- Micro D38999

- MIL-DTL-27599

See also:

Mil-Spec Circular Connectors Product Roundup

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024