University Taps “The Heat Beneath Our Feet” Geothermal Energy

Colorado Mesa University’s geothermal-exchange system is a feature project of the Western Governors’ Association initiative showcasing the benefits of geothermal energy.

In 2007 Colorado Mesa University (CMU) in Grand Junction began its transition from a commuter campus of about 3,500 students to the campus of 10,000 students it is today. “That growth required the university to build lots of new buildings for classrooms, residence halls, and a new university center,” said Kent Marsh, vice president of capital planning, sustainability, and campus operations. “At that time, an institution of higher education receiving state funding for capital construction or renovation had to meet or exceed LEED Gold standards, which is a really high standard. One of the ways to get there is to install the most efficient HVAC system available. That’s where the conversation started. The most efficient HVAC system we can install in western Colorado turned out to be geothermal-exchange.”

One of the largest geo-systems in North America, CMU’s system heats and cools 1.2 million square feet of academic and auxiliary buildings. The project started with the first new classroom building. The next building under construction was the University Center. “At the time, we thought, what if we connected the University Center into the same drill field that the classroom building is connected into?” said Marsh. That’s what they did, eventually expanding with another four or five drill fields and connecting a total of 16 buildings.

Inspired by CMU’s success, the Western Governor’s Association, chaired by Colorado Governor Jared Polis, kicked off its 2021 initiative, The Heat Beneath Our Feet, at the campus to promote one of the regions’ prime assets: geothermal energy. The initiative continues to build on projects like the one at CMU, to expand the use of this cost-effective, renewable energy source that is abundant throughout the Western United States.

How it works

CMU’s geo-grid consists of a complex network of geo-exchange systems that heats or cools the air as needed. The system circulates water through long stretches of high-density polyethylene pipe buried vertically to a depth of 500 feet, where the temperature is a constant 54 °F. “The ends of the pipe are heated and thermally fused together. Because there is no mechanical connection there’s very little, if any, chance of it breaking over time,” said Marsh.

The system is a closed loop that continuously recycles the water. Thermal energy is exchanged between the earth and the water in the pipe. In the hotter months, heat pumps inside buildings extract heat from the indoor space and transfer it into the water circulating in the geothermal system. Heat is extracted from the central loop by the earth. In colder months, the water gains heat from the ground and releases it into the buildings, via a heat pump, to heat the air.

The central loop moves heat where it is needed. If heat builds up in one area, it is directed to another part of the building or to another location that needs it. “Our region is cooling dominant, which means that we cool more days of the year than we heat. Heat is likely to build up and so we have too much heat rather than too little,” said Marsh.

The campus’s 800,000-gallon Olympic-sized pool doubles as a heat sink; excess heat from the central loop economically heats the pool. Additionally, the system is used to heat the water in the residence halls and elsewhere. Domestic water comes in from the tap at 60 °F and needs to be heated to 120 °F. Waste heat can take that water to about 90 °F, reducing the amount of energy needed by a water heater to get it the rest of the way, Marsh explained.

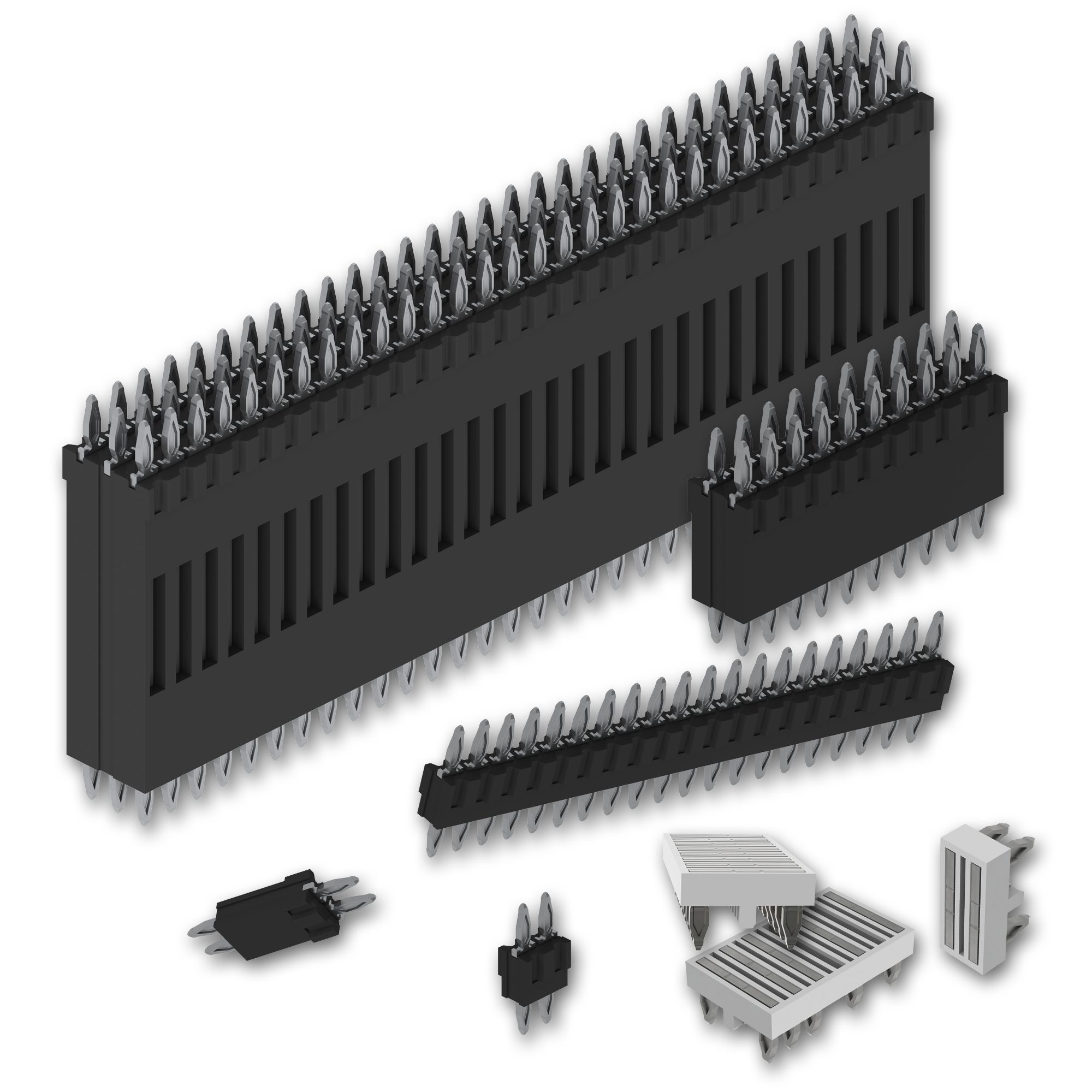

Ept’s Zero8 0.8 mm PCB can survive temperature fluctuations and corrosive gases within a geothermal heat pump. With double-sided robust contacting technology, connections can be maintained securely even during vibration activity. An optional EMC shielding prevents outside interference from other electronics nearby. It’s capable of handling data transfer at high speeds of up to 16 Gb/s.

The electrical connection

The geothermal-exchange system relies on electricity. Unlike a furnace that uses gas to heat and electricity to cool, the heat pump uses electricity to do both. Every building on the system has a heat pump and a traditional water pump (also run with electricity) to move the water between the buildings, the central loop, and the ground. The direct digital controls, a kind of glorified thermostat, is a computer program that runs all the equipment in a building and is all electrical. Electronic sensors throughout the system sense whether the water is too warm or too cold and tell the software to start sending loop water into the ground to get rid of excess heat, for example.

Flexilink from ept is a rugged and durable two-sided 2.54 mm grid PCB connector. It has up to 11 A current rating per pin and can withstand high voltage fluctuations that other connectors may find very challenging but is critical for geothermal or hydropower systems. Flexilinks are also excellent for designs that need durability and high vibration tolerances, allowing complex equipment to run for longer periods of time and preventing expensive maintenance.

Benefits of geothermal energy

The geothermal-exchange system at CMU significantly contributes to the university’s sustainability goals, which includes being the first university in the country to be fully heated and cooled by a geo-exchange system. The system reduced the university’s carbon footprint by 17,742 metric tons of CO2 per year, while providing 2,728 tons of energy-efficient heating and 3,113 tons of energy-efficient cooling. It is responsible for 90% of the energy required to operate the campus.

The system also reduces operating costs. “A traditional system, the one you probably have in your home, consumes around 22 kilowatt hours of electricity per square foot of building per year. A geo system is far more efficient, consuming less than half or about 10 kilowatt hours per square foot per year. So that 12 kilowatt hours difference means that instead of buying 12 kilowatt hours at 14 cents per kilowatt, we’re saving that amount of money. This means we don’t have to raise our tuition as much as we would have with traditional HVAC,” explained Marsh. CMU has saved nearly $12 million in energy costs since 2008. The cost predictability over time allows CMU to offer the second lowest tuition rate in the state.

The sustainable future

As the campus continues to grow, additional drill fields will accommodate a larger system to service more existing buildings as well as new development. This also opens the potential to expand into the greater community, for example to a nearby high school and businesses. “What if Xcel Energy or the City of Grand Junction provided a geothermal resource along with the other utilities they provide? Rather than simply replacing an old furnace with a newer model, customers would have the option of adding a heat pump and connecting to this resource,” said Marsh. He described the potential for more drill fields to connect subdivisions to the central loop system that would all work together to move heat, not only between buildings on the CMU campus, but between buildings throughout the community.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024