Lightweight Connector Innovations Enable Infotainment on the Go

Consumers are now accustomed to instant, high-quality sound and image technology everywhere they go. For airlines, lightweight connector innovations make it possible to provide entertainment while keeping size and weight down.

Connector innovations give designers size, weight, and power (SWaP) advantages and make it possible to provide air travel passengers with the infotainment they expect, as well as adjustable lighting and other cabin comforts.

To enable more capabilities in systems and devices, aircraft designers are embedding more electronic components — including sensors, connectors, relays, and fiber-optics — throughout the chassis or airframe. In fact, the use of electronics in airplanes has risen from 10% of the total cost of airplanes built in the 1980s to 40% in today’s aircraft, inspired, no doubt, by the similarly growing demand for more connected vehicles and the popularity of in-car entertainment systems. As the need to integrate higher levels of technology to meet consumer demands increases, aircraft engineers face a critical challenge: Getting enough power to devices and applications, while also reducing the size and weight of the electronic packaging. Lightweight connectors are the solution.

Almost every aviation electronics application is subjected to SWaP challenges. Conventional metallic circular connectors designed to handle battlefield and aerospace environments are a time-tested solution for robustness and performance, but not so much for weight and space reductions. As a lighter weight alternative, aerospace-qualified rectangular connectors that hit the SWaP sweet spot within a smaller performance envelope are now available.

Rectangular Connectors put Designers in a Better Place

For example, 369 Series connectors from TE Connectivity are specifically designed to address power and low-speed data needs for seat wiring and actuation, lighting, and on-board entertainment systems. Based on ARINC 800 and EN4165 standards, 369 Series inline connectors feature a rectangular shape that enables space-efficient stacking. A scoop-proof interface is particularly suitable for blind-mating and low visibility conditions, and a button-latching mechanism secures the mated connectors. In addition, shells are made from high-performance composite materials that meet aerospace low smoke, toxicity, and flammability requirements.

TE’s 369 series connectors are specifically designed to address power and low-speed data needs for seat wiring and actuation, lighting, and on-board entertainment systems.

Rectangular Modules add Performance with Less Weight and Space

Of course, in-flight infotainment systems require substantial bandwidth.

Higher throughput requires faster network speed at the edge to make real-time data and streaming video possible. For infotainment manufacturers, innovative connector solutions open doors for generating business value — from interactive infotainment applications engineered for immersive engagement with real-time information, on-demand entertainment, artificial intelligence, and the Internet of Things — and not just in cars and airplanes, but also in buses, trucks, and trains, and even high-use buildings and public spaces.

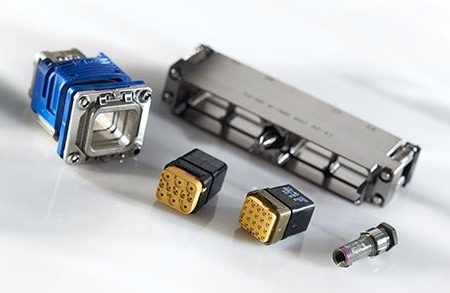

Once again, a lightweight connector with a rectangular form factor provides significant advantages. For example, DEUTSCH DMC-M connectors from TE in rectangular multi-cavity and single-module configurations offer a compact, lightweight connectivity option. For enhanced robustness and weight savings, shells are available in aluminum alloy or composite with nickel or cadmium plating to withstand harsh environments. To meet EN4165 and other avionics specifications, a wide range of contact arrangements and insert layouts can be specified to support coaxial, quadrax, high-speed Ethernet, or optical contacts.

Once again, a lightweight connector with a rectangular form factor provides significant advantages. For example, DEUTSCH DMC-M connectors from TE in rectangular multi-cavity and single-module configurations offer a compact, lightweight connectivity option. For enhanced robustness and weight savings, shells are available in aluminum alloy or composite with nickel or cadmium plating to withstand harsh environments. To meet EN4165 and other avionics specifications, a wide range of contact arrangements and insert layouts can be specified to support coaxial, quadrax, high-speed Ethernet, or optical contacts.

When devising a particular solution, a designer should consider the circuit conditions and the electrical, mechanical, environmental, and bandwidth specifications. The designer should also be aware of the trade-offs in installation and maintenance of a given connector system.

Evaluating the advantages of different connectivity options for aviation, automotive, and infotainment electronics is a complex subject. Beyond choosing the right components, designing robust integration and building future-ready solutions come into play. Connectivity options for sensors, antennas, and driver assistance, infotainment, and multimedia systems — as well as the needs of 5G, high-speed Ethernet, and fiber optic links — are all part of the specification process. The right components enable end-to-end connectivity solutions to meet today’s SWaP and bandwidth challenges and make air travel more enjoyable.

By Clint Schlosser, Product Manager at TE Connectivity

See the white paper, “Next-Generation Infotainment Technology: Engineering the Connected Future,” by TE Connectivity, to learn more.

Like this article? Check out our other Connector Basics, Consumer Electronics, Aviation, Transportation, and 2019 articles.

- Lightweight Connector Innovations Enable Infotainment on the Go - February 26, 2019