Innovative Connector Solutions from Industrial to UxV

Industry-standard connectors have their place, but sometimes an innovative connector solution is required to solve unique design challenges. Distinctive connector designs help design engineers in the industrial and unmanned and autonomous (UxV) sectors achieve advanced power and data goals.

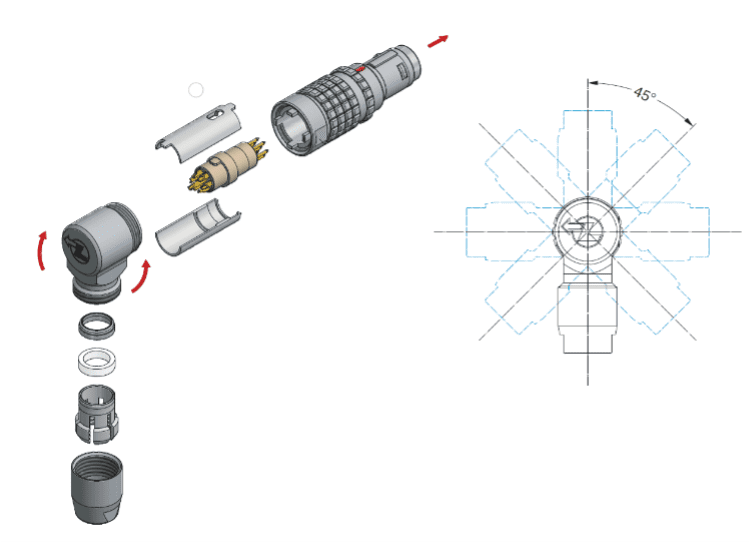

Innovative connector solutions are needed to accomplish the data and power needs of leading-edge applications. Cable management is important for applications with limited space. Industrial controls often have many cables that must be managed to minimize flex and wear. Similarly, in UxV applications connectors and cable routing must fit into very tight spaces. Ordering a traditional elbow connector plug with a fixed cable exit angle can limit cable management options. One remedy is to rotate the receptacle to achieve the desired cable exit angle. However, this may be a challenge if the PCB has already been produced. With a more unconventional but more versatile choice, such as the Anglissimo push-pull plug, the cable exit angle can be selected for any of eight different angles during assembly. Even after assembly, the cable exit angle can be adjusted by removing the shell and re-positioning it to the desired angle.

Blind mating must be done when a connection needs to be made in dark or difficult to reach locations. Keyed connectors have forms that enable a connection to be made by feel alone, but irregular connector housing shapes can present a challenge in tight spaces. Here’s where an innovative connective solution can make the difference needed. A multi-concentric insert can also be mated by feel within a round interface, and this design allows the connector to be rotated once mated, or even during mating. This can be helpful in an industrial control application where a twisted cable can easily be straightened by rotating the connector. Another benefit is that the connectors can be mounted in a tube and engaged axially or during rotation. Most industry-standard multi-concentric connectors are available in coax or triax configurations which only allow two to three contacts. The multi-concentric product is possible for up to 10 contacts, plus an outer shield. The larger surface area of the contacts also allows for higher current in a small package for power applications.

Connection status can add real-time feedback to those using industrial control equipment. How do users know the connector is properly mated, power or data is properly flowing through the connector, or if the device at the other end of the cable is functioning properly? A quick check of the panel receptacle indication lights can provide a lot of information. The HALO LED product integrates active LEDs right into the receptacle flange. They can be programmed to light up when connected, flash if there is an open or short circuit, or even change color by means of pulse width modulation circuitry designed into the PCB. Over a million color options are included, as well as three LED options: full 8 LEDs, a small single LED, or a small ring of light.

Limitations of M8 and M12 Type Connectors

Industry-standard M8 and M12 connectors

Industry-standard M8 and M12 connectors are widely used across industrial, transportation, and other heavy equipment markets, but they also leave a lot of room for improvement. Traditionally, these connectors have simple threaded coupling and only handle a few signal contacts. However, the terminations may be overmolded, which limits the ability to repair a cable if needed. Also, the contacts may be stamped and rolled, which can limit cycle life and reliability. (Contacts that are machined from solid brass or bronze have much greater durability.)

To improve performance for threaded coupling connectors, the use of a detent or ratchet coupling can be incorporated into the connector design. Insulators can be designed to accommodate signal as well as power and even fiber optic, high voltage, or fluidic/pneumatic functions. Utilizing a single connector solution to incorporate all design elements saves space and helps the end user quickly connect or disconnect the cable.

Interconnect designers continually create innovative connector products to help engineers design streamlined and effective wiring architectures that can meet the increased functionality advanced technologies require. New concepts are developed in partnership with customers and design engineers whose challenges might lead to the next great connector innovation.

Visit LEMO Connectors to learn more about innovative solutions for industrial applications.

Like this article? Check out our other How to Specify, circular connectors articles, our Industrial Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Innovative Connector Solutions from Industrial to UxV - July 12, 2022