Flow and Pressure Sensors 101

Designed to capture and analyze vital parameters guiding the behavior of fluids in a system, flow and pressure sensors provide system operators with transparency into their systems. These insights can help improve system safety, efficiency, and performance.

A flow sensor is an electrical component that measures the rate of flow of a fluid or gas. Flow sensors analyze the electrical and/or mechanical behaviors of a system to convert the flow rate of a substance into an electrical signal that can be interpreted by a processor or microcontroller.

Volume flow rate is defined by the equation , where Q is the volume flow rate in units of meters cubed per second (m³/s), V is the volume through which the fluid flows in meters cubed, t is the time in seconds, A is the cross-sectional area of the fluid, and v is the velocity of the fluid. Flow is also defined by the equation of continuity for incompressible liquids, which states that .

Different types of flow sensors offer unique working principles, advantages, and disadvantages.

Differential pressure flow sensors restrict the liquid flow and calculate the pressure difference that results across that restriction. The measured differential pressure is then converted into velocity data and flow rate. These sensors take advantage of the fact that the flow rate is directly proportional to the square root of differential pressure.

Thermal mass flow sensors exploit the relationship between heat transfer and liquid velocity. These devices consist of a heating element that transfers heat to the liquid and a temperature sensor that measures the heat absorbed by the liquid, which is then converted into flow data. In these systems, the mass flow can be calculated using the following equation: Where W is the mass flow, H is the heat input, T is the temperature, and Cp is the specific heat at a constant pressure.

Turbine flow sensors place a spinning part in the direction of fluid flow. The spinning part is agitated by the fluid’s movement, and its rotation around its axis is measured and used to determine the flow of the fluid.

By converting these flow data into usable electrical information, flow sensors enable precise control, optimization, and analysis across a wide range of applications, such as tracking the amount of air through an engine’s intake manifold, measuring the flow of gases in ventilators and anesthesia workstations, and verifying fluid flow in manufacturing processes.

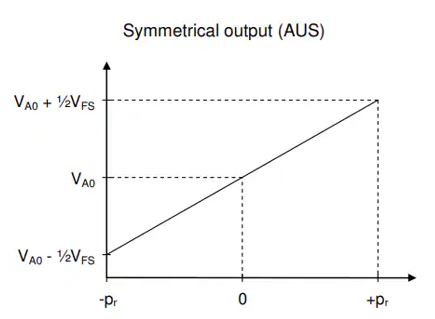

Symmetrical output of a TDK capacitive pressure sensor. (Source: TDK)

Because of the variety of options available, selecting the correct flow sensor for your design may be a challenge. Some common requirements to consider include cost, accuracy, resolution, area, and power consumption. Generally, differential pressure flow sensors are the most popular due to their low cost, high performance, and versatility.

This article was originally published by Mouser Electronics at www.mouser.com/applications/introduction-flow-and-pressure-sensors.

Like this article? Check out our other Manufacturing articles, our Sensors Market Page, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Flow and Pressure Sensors 101 - August 4, 2023