Designing with Waterproof USB Type-C Connectors

As small consumer electronic devices infiltrate every aspect of our lives, they endure lots of rough handling and occasional accidents. The connectors that empower these systems must protect functionality and signal integrity when a device is splashed on, spilled on, or even dropped into water. Waterproof USBs are up to the challenge.

Consumer electronic products are now equipped with higher component densities, transfer larger files, have increased power needs, and are used in more demanding environments. That means traditional connectivity solutions no longer measure up. While legacy Universal Serial Bus (USB) and Micro USB connectors have been the prevailing standard for device connectivity since the 1990s, USB Type-C is becoming the preferred connector solution for today’s consumer products because it offers higher performance combined power and data connectivity and a form factor that fits today’s products. True IPX8-rated waterproof USB Type-C connectors (i.e., those tested to protect from water ingress at up to one meter of water immersion) are increasingly needed to meet customer requirements. In this article, we’ll look at the advantages of USB Type-C connectors and discuss selection and design considerations for using waterproof USB Type-C connectors.

Consumer electronic products are now equipped with higher component densities, transfer larger files, have increased power needs, and are used in more demanding environments. That means traditional connectivity solutions no longer measure up. While legacy Universal Serial Bus (USB) and Micro USB connectors have been the prevailing standard for device connectivity since the 1990s, USB Type-C is becoming the preferred connector solution for today’s consumer products because it offers higher performance combined power and data connectivity and a form factor that fits today’s products. True IPX8-rated waterproof USB Type-C connectors (i.e., those tested to protect from water ingress at up to one meter of water immersion) are increasingly needed to meet customer requirements. In this article, we’ll look at the advantages of USB Type-C connectors and discuss selection and design considerations for using waterproof USB Type-C connectors.

Connectivity Trends

Waterproof electronic components are a prevailing trend in the consumer device industry because users want to be able to take their phones, tablets, watches, monitors, and other small electronics with them wherever they go. Manufacturers of the iPhone, Samsung Galaxy, Huawei’s high-end phones, and other smartphones tout their products’ water resistance to consumers. This desirable attribute also applies to other products, like electric shavers, electric toothbrushes, point-of-service terminals, wearables, and automotive, medical, and industrial products. The last thing users want to worry about is environmental sensitivity in an electrical product, particularly in environments where water is a hazard.

Another major trend is faster operation. Users want products to both transfer data more quickly and charge more quickly. The market is transitioning from Micro USB to USB Type-C because USB Type-C delivers 10 times the power and data rates of its predecessor. For example, a product with a USB 3.0 Micro USB connector might have used 0.9A to charge, while a USB Type-C connector can use up to 5A to charge much more quickly. In addition, although Micro USB data transfer rates are in the 5Gb/s range, USB Type-C data transfers can deliver up to 10Gb/s and this extra speed makes a big difference when transferring large files from one device to another.

Finally, ease of use is a constant goal for designers of consumer products. USB Type-C connectors are easier to use than Micro USB because they offer reversible, or flip insertion, so no specific connector orientation is required when inserting them into the device port.

TE Connectivity’s miniature USB Type-C receptacles have one of the smallest dual-row SMT footprints for critical board space savings and offer optional IPX4-rated splash-proof protection in addition to higher power and data handling capabilities and a reversible mating face.

Key USB-C Connector Requirements

Individual device designs will have unique requirements that dictate the selection of a USB Type-C solution. Designers will focus on three key areas as they evaluate the needs of a specific design and select a connector product that can deliver the needed performance.

Signal Integrity: Higher signal integrity equals faster data rates, so USB Type-C products with optimum signal integrity are preferred and should be rated for USB 3.1 performance. A USB Type-C port can run at 5Gb/s but some manufacturers have leveraged their experience with previous data products to deliver 10Gb/s throughput.

Power: USB Type-C products can transfer more power — up to 100W at 5A compared to 10W at 0.5A in a Micro USB system — so devices can charge more quickly, assuming the rest of the system is designed for faster charging.

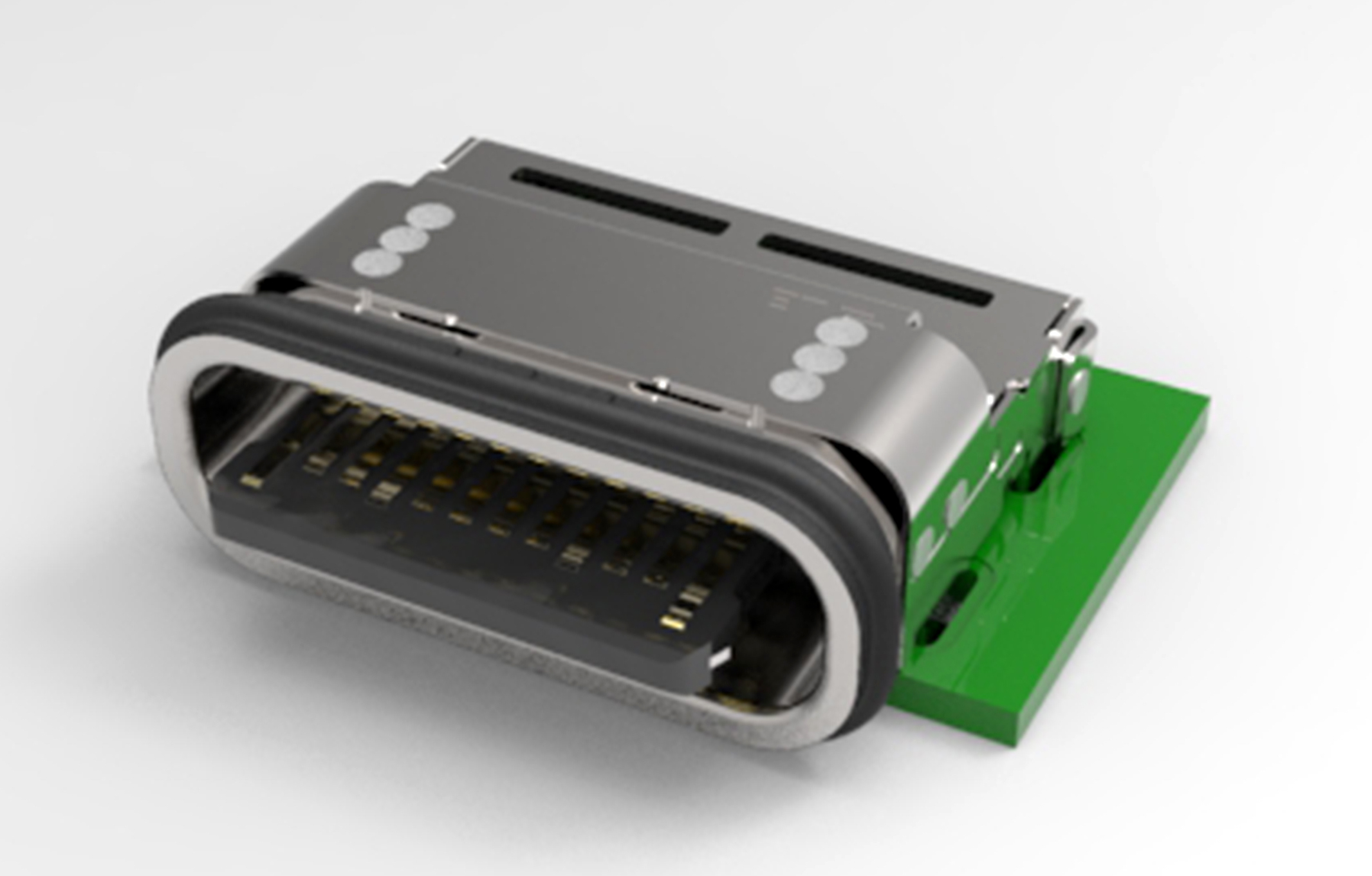

Environmental Protection: To provide the environmental protection users require, waterproof USB Type-C connectors leverage a rubber seal and a seamless housing to keep water out. These connectors should be rated for IPX8 water ingression performance (per IEC 60529) and should be durable enough for thousands of mating cycles. Added board retention features help make for a robust design, providing high reliability and overall device quality.

TE Connectivity’s waterproof, onboard, USB Type-C connectors are designed to help protect devices including wearables, smartphones, appliances, medical equipment, and automotive infotainment systems from harsh-environment conditions. Features include industry leading IPX8 dust and water ingress protection, which allows them maintain a reliable connection at a depth of 1.5m for a minimum of 30 minutes, enhanced EMI protection and board retention, 10Gb/s and 100W data and power handling capabilities, a user-friendly reversible mating interface, and compatibility with a variety of protocols.

USB Type-C connectors with IPX8 waterproofing performance are becoming the new standard for a wide range of products because they deliver go-anywhere reliability, faster charging, and faster data transfers. Micro USB has had a good history of delivering connectivity in a wide range of products, but USB Type-C is the connector of the future.

Caitlyn Adams is the global product manager within TE Connectivity’s Data & Devices business unit responsible for AMPLIMITE D-Sub connectors, mini spring sockets, and the USB Type-C connector portfolio.

Like this article? Check out our other Connector Basics and Waterproof Connectivity articles, our Consumer Electronics and Datacom/Telecom Market Pages, and our 2020 and 2019 Article Archives.

- Designing with Waterproof USB Type-C Connectors - February 25, 2020