Problem Solved: Time to Look Beyond Gold Plating?

Time to Look Beyond Gold Plating

Connector suppliers looking to establish new gold plating lines frequently run into trouble when seeking licenses for new operations. Licensing authorities, particularly in China, have become reluctant to approve further licenses, which is understandable given the environmental risk and potential health hazards of gold plating.

Swedish company Impact Coatings has introduced a new type of machinery that provides a viable alternative to wet gold plating, using high-volume physical vapor deposition (PVD). In the past, PVD has been seen as a slow and cumbersome process compared to wet plating, but Impact’s new equipment matches the productivity of a modern gold plating line, using a non-toxic process with the gold replacement material Silver MaxPhase. The new process reduces costs, has a smaller footprint, is easily installed, and, above all, needs no special licenses.

Physical Vapor Deposition

Physical Vapor Deposition (PVD) is a method of treating a surface through condensation of the coating material and subsequent deposition onto the substrate. The process takes place under vacuum using dedicated machinery. The method can be used to produce very thin films of most inorganic (and some organic) materials on a variety of surfaces with very high adhesion. In general, coatings consist of metals, metal alloys, or ceramics, usually nitrides, carbides, and oxides. The method is highly flexible and the thicknesses of the coatings can be varied from a few atomic layers up to approximately 10 µm. By offering a wide range of coating materials and thicknesses, PVD coatings can be custom made to achieve specific electrical, mechanical, optical, and decorative properties.

The substrate (i.e. the coated object) can be metallic, but also non-conductive materials like plastics, ceramics, and other non-metallic isolators can be coated. The option of maintaining low process temperatures, below 100ºC (212.00F), further increases the range of possible applications.

PVD is used in a wide spectrum of industrial applications. The most common are semiconductors, CD/DVD-media, tools, mechanical components, automotive components, sensors, biomedical equipment, optics, etc. The use of PVD is increasing rapidly, replacing less environmentally friendly chemical and galvanic methods.

Performs Like Gold

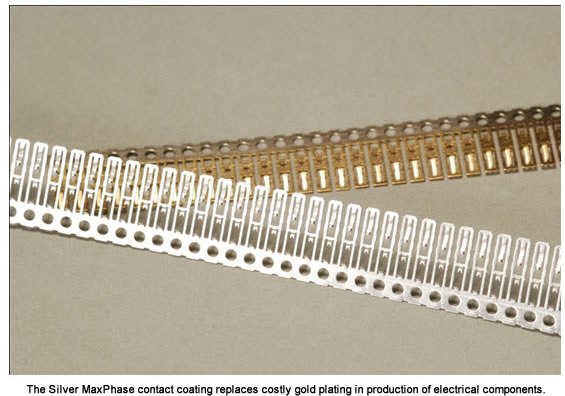

Impact Coatings’s method is to apply a substitute for gold as contact coating for the electronics industry, using PVD. Silver MaxPhase, a metal alloy that performs like gold in terms of electrical conductivity and resistance to wear and corrosion — but at a fraction of the cost — is used. This results in significant cost savings and cost control for connectors and other electrical components.

Applying Silver MaxPhase with PVD is an environmentally friendly process, unlike wet-plating with gold, which uses cyanide, a highly toxic substance. The environmental concerns over gold plating have resulted in restrictions and a total stop in plating licenses in key regions for electronics manufacturing, such as parts of China. Resulting limitations in production capacity and high costs for moving plating lines and conforming to new legislation has caused a capacity crunch for the electronics industry, as it is difficult to obtain permissions for new plating plants and existing plants are often operating at capacity.

In this situation, PVD offers a completely clean alternative that can easily be set up anywhere as a turn-key solution. The process does not require water and waste treatment facilities or government licenses for production lines. The production equipment can even be moved, should the need arise.

High and unpredictable gold prices cause additional headaches for electronics manufacturers. The price of gold is up six times since 2000 and is expected to continue rising. By replacing gold with Silver MaxPhase, costs are reduced and become predictable over time.

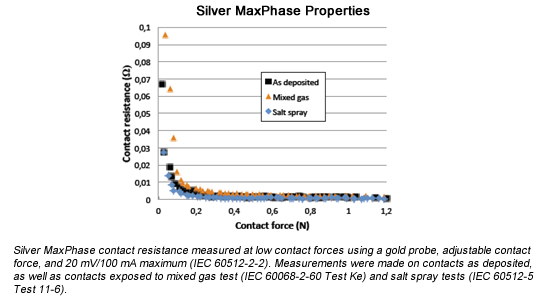

For Low Voltage and Low Contact Force

Silver MaxPhase provides electrical properties and resistance to corrosion and wear that were previously only possible using costly noble metals. The contact coating is qualified for low-voltage and low-contact force connectors that were previously gold-plated, e.g. battery and I/O connectors for mobile phones (according to IEC 60512 and IEC 60068 standards). An average mobile phone, for instance, has five to 10 connectors that could be coated with Silver MaxPhase. Qualification is ongoing for telecom, industrial, consumer, computers, and other product groups. Silver MaxPhase typically replaces gold on nickel-plated, copper-based connectors. It also works well as a contact coating directly on stainless steel, completely eliminating the need for wet plating processes.

High-Volume, Standalone Equipment

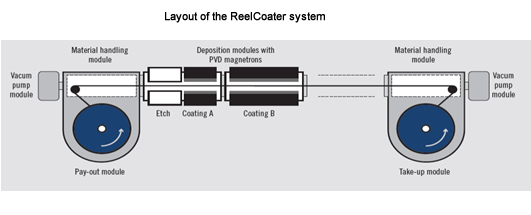

The PVD plant is stand-alone equipment with a small footprint, yet with productivity similar to modern gold plating lines. Silver MaxPhase can be coated both reel-to-reel and in batches of individual parts. The ReelCoater is designed for PVD coating of metal strips reel-to-reel. Multiple reels can be loaded and, depending on the geometry of the strips, up to eight strips can be coated in parallel. The reels and strip material are loaded inside the system vacuum chamber to allow optimal coating conditions under high vacuum. The ReelCoater has a modular configuration, where system modules can be added or removed and the strip type can be changed. Layered coatings of different materials can be made in the same ReelCoater line. Apart from coating materials, the system only requires electrical power, cooling water, compressed air, inert gas for the deposition, and clean air for ventilation. Simple utilities, easy operation, and a small footprint make the equipment easy to integrate into existing reel-to-reel manufacturing.

With efficient and environmentally-friendly process methods, PVD can offer a way forward for electronics companies looking for a green alternative.

Peter Högfeldt manages marketing and sales to the connector industry at the Swedish company Impact Coatings AB, which he joined in 2007. He has two decades of electronics industry experience from various product marketing and sales positions. Peter has a Master of Science degree in applied physics from Linköping University, Sweden, which he received in 1997.