The Differences Between MIL-DTL-38999 Series I, II, and III Connectors

These circular connectors were originally designed to meet requirements for cable-to-panel applications in the military and aerospace market. Now they are used across a wide range of industries that benefit from their high-performance qualities.

By Air Electro, Inc.

The engineers and procurement professionals in both the civil and military aerospace industries work with QPL-approved (Qualified Parts List) connectors on a daily basis. Constant exposure and ingrained routines can cause people to forget some of the basic concepts of the products they work with most often, like the differences between the MIL-DTL-38999 Series I, II, and III connectors.

MIL-DTL-38999 Series I Connectors

MIL-DTL-38999 Series I connectors are circular, high-density, bayonet style connectors available in shell sizes ranging from #9 to 25 with more than 50 QPL-approved insert arrangements. They were originally designed to meet high performance requirements for cable-to-panel applications in the military and aerospace market. Today they are widely employed in applications such as marine electronics, communications equipment, medical instrumentation, weapon systems, armored carriers and tanks, and test equipment.

Air Electro stocks SOURIAU’s 8LT Series MIL-DTL-38999 Series I connectors.

The shells of MIL-DTL-38999 Series I connectors are made of aluminum alloy and are available with one of four conductive plating options — black zinc nickel, olive green cadmium, nickel, or green zinc cobalt — to provide electrical continuity between the mated shells prior to contact engagement. They are also polarized to ensure proper orientation of the mating halves prior to electrical engagement. Shell types include square flange receptacles, in-line receptacles, short square flange receptacles that do not accept backshells, square flange receptacles for rear mounting, jam nut receptacles, plugs with radio frequency interference (RFI) shielding, and plugs with RFI shielding that do not accept backshells.

MIL-DTL-38999 Series I connectors also offer removable, rear-release pin or socket contacts with crimp terminations that meet QPL SAE AS39029 requirements, thermocouple contacts, and PC-tail contacts for commercial use. The insert arrangements in these high-density connectors can accommodate up to 128 pins with contact sizes ranging from large (size 4) to small (size 26). EMI shielding capabilities and hermetic sealing options are available as well.

MIL-DTL-38999 Series II Connectors

MIL-DTL-38999 Series II connectors are circular, high-density, bayonet style connectors with low-profile shells in sizes ranging from #8 to 24 with more than 40 QPL-approved insert arrangements. Originally designed for use in civil and military aerospace applications, these high-reliability connectors feature EMI shielding and excellent resistance to shock and vibration and fluid ingress, and are now also used in marine electronics, communications equipment, medical instrumentation, weapons systems, armored carriers and tanks, and test equipment.

Air Electro stocks Glenair’s hermetic MIL-DTL-38999 Series I, II, III, and IV connectors.

These connectors also have aluminum alloy shells with conductive plating options that provide electrical continuity between the mated shells prior to contact engagement — including black zinc nickel, olive green cadmium, nickel, and hard anodized finishes — and polarization features that ensure proper orientation of the mating halves prior to electrical engagement. A variety of shell types are available in this series, which includes front- and rear-mount square flange receptacles with or without accessory threads, in-line receptacles with accessory threads, jam nut receptacles with accessory threads, and plugs both with and without RFI shielding.

D38999 Series II connectors also offer removable, rear-release pin or socket contacts with crimp terminations (AS39029), as well as thermocouple contacts and, for commercial applications, PC-tail contacts. These high-density connectors accept insert arrangements that accommodate up to 128 pins in sizes ranging from large (size 12) to small (size 22D) and are also available with EMI shielding capabilities and hermetic seals.

MIL-DTL-38999 Series III Connectors

MIL-DTL-D38999 Series III connectors are the most prevalent military circular connectors on the market and meet Boeing specification BACC63 and Airbus specification EN3645. These circular, high-density, screw-coupling connectors are available in shell sizes ranging from #9 to 25 with more than 50 QPL-approved insert arrangements and deliver high-reliability performance in harsh-environment applications with operating temperatures up to 200°C and high vibration up to 44g for 500 mating and unmating cycles. They were originally designed for civil and military aerospace applications, but are now used for marine electronics, communications equipment, medical instrumentation, weapons systems, armored carriers and tanks, and test equipment.

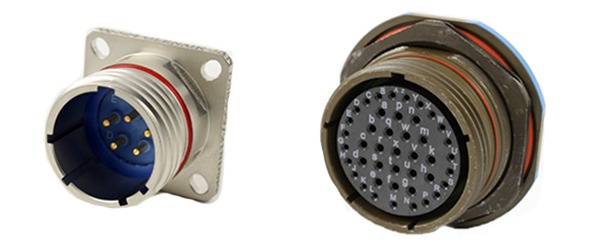

Air Electro stocks MIL-DTL-38999 Series III connectors manufactured by both SOURIAU (left) and Corsair (right).

A variety of QPL-approved shell materials are available for D38999 Series III connectors, including aluminum, stainless steel, lightweight composite, titanium, and bronze. Plating options for aluminum shells include cadmium olive drab, nickel, black zinc nickel for ROHS compliance, and green zinc nickel cobalt; plating options for composite shells include cadmium olive drab and nickel; and plating options for stainless steel shells include passivated and nickel finishes. Titanium shells are available without plating and bronze shells are characteristically unplated.

Shell types include square flange receptacles, jam nut receptacles, and plugs, and contact options includes removable, rear-release pin or socket contacts with crimp terminations (AS39029), thermocouple contacts, and PC-tail contacts as a commercial option. These high-density connectors have insert arrangements capable of accommodating up to 128 pins in sizes ranging from large (size 4) to small (size 22D), have polarization features designed to assure proper orientation of the mating halves prior to electrical engagement, and are available with EMI shielding capabilities and hermetic seals.