What are Push-In Wire Connectors?

Meet the Connector: Push-in Wire Connectors

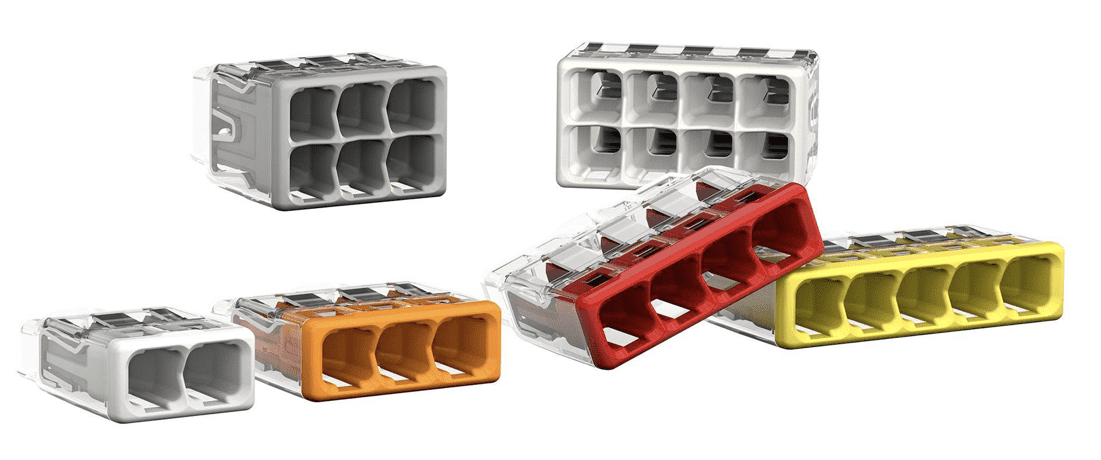

Push-in wire connectors are insulated wire connectors that are used in electrical systems, including commercial and residential lighting, digital signage, and other building electrical systems. They are used in place of traditional twist-on connectors or wire nuts. This connector type is easy to use, enables fast connections, and often features color-coding for easy identification.

These simple connectors are designed for ease of use. Most push-in wire connectors require no special tooling; installers simply insert wire conductor ends into ports or slots in the connector terminal. Push-in wire connectors are typically self-latching; an internal spring clamp secures the stripped wire, although some versions secure with an external latching mechanism, such as a lever or clamp. They are available with one or more ports; only one conductor should be used per port. To disconnect, simply twist and pull the wire. These connectors may be reused with solid (not stranded) wire of the same size or smaller.

Push-in wire connectors are a variation of earlier mechanical connectors that work with bare wires, such as terminal blocks, screw-in connectors, and wire-splice connectors. Innovations today center on color coding and materials; for example, color coding or transparent polycarbonate material that enables installers to visually confirm proper connections. New compact form factors help streamline installations.

HellermannTyton’s HelaCon push-in wire connectors (available from Mouser Electronics) can be applied tool-free using the push-in technology. HelaCon Plus Mini uses a double spring which is approved for solid and stranded wires.

Design Notes

Specifications: Push-in wire connectors meet a range of specifications depending on the manufacturer but are typically UL listed and meet CE electrical code. RoHS, ANSI, DIN, and EN specifications may also apply.

Coding: Color coding helps installers identify the correct cables for retrofit, repair, and installation.

Cable Considerations: Push-in wire connectors are available in a variety of sizes and opening diameters to accommodate a range of cable and wire gauges. They typically include from one to eight ports. Some versions are designed for stranded wire and others for solid wire.

Current Rating: Maximum current allowed depends on individual products but range from 24 A. Voltages range from 450 V to 1000 V.

Safety: Some versions feature a voltage-testing port or slot in which a multimeter probe can be inserted.

WAGO’s Push-Wire connectors feature transparent housing for checking the conductor position and correct stripping length. Low insertion forces and high retention forces help protect the contact.

Materials: These connectors are available in opaque as well as transparent plastic or polycarbonate materials.

Ruggedization: This type of connector is available in commercial versions (often available at hardware stores) as well as more durable, professional-quality versions by trusted connector suppliers. The difference in quality between those two categories is significant, and the latter is used in situations where repair, reuse, upgrades, and long-term use is important.

Handling Advantages: Push-in wire connectors are designed to provide fast and easy connections with low insertion force. They are used by consumers for DIY home repairs as well as by professional electricians and tradespeople.

Markets, Sectors, and Applications

Home and building wiring, lighting installations, digital signage, distribution boxes, and junction boxes.

Molex’s See and Splice Series of push-in wire connectors (available from Digi-Key Electronics and Mouser Electronics) feature a fully transparent housing and accommodate 12 to 24 AWG wire.

Suppliers

Push-in wire connectors are available from many manufacturers, including HARTING, Molex, Phoenix Contact, TE Connectivity, WAGO, HellermannTyton, and 3M.

TE Connectivity’s push grip wire connectors are color coded for easy identification and compact for space-constrained applications. These connectors provide a visual termination of 22-12 AWG solid and stranded wires.

Related Products

- Terminal blocks

- Twist-on or screw-in wire connectors

- Wire nuts or lever nuts

Like this article? Check out our other Meet the Connector, circular connectors, and Market Update articles, our Medical Market Page, and our 2022 and 2021 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024