Test to Perfection: Product Reliability Begins with Rigorous Connector Testing

Rigorous testing of every element in an integrated circuit, from connectors to PCBs, is a critical step in the product design process.

As more electronics move into complex and high-reliability application environments, the need to measure their attributes and performance, and test their endurance over time and under specific conditions, has become a critical step in the development process. Products and the components inside of them must operate reliably and meet regulatory expectations for safety, conformability, and compatibility. Test & Measurement is the discipline that adds certainty and science to the development and performance of interconnects and other components, PCBs, and the final products they support.

Connector Testing

Interconnects are the subject of test processes, and they also play a key role in test equipment that is used to test other components and systems. Many connector suppliers have expanded their offering to include rugged, specialized products for Test & Measurement. These products are used by equipment test labs, regulatory bodies, OEMs, product development designers, research, and other entities that conduct tests in-house to guarantee, understand, and innovate their products.

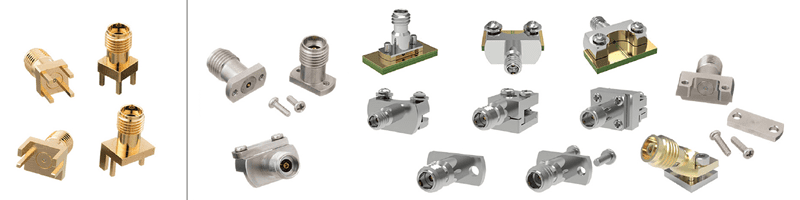

Over the past decade, CarlisleIT is one company that has developed specific solutions for this area, with a special focus on radiofrequency (RF) technologies, said Rory Becerra, T&M product manager for the company. “Our company has a lot of heritage with RF connectors. For instance, we do high-end PCB connectors for the military market, with the ultimate traceability and qualification. We realized that we could leverage our designs, capabilities, and resources, and transfer them to products for test labs and any market that needed that level of performance without getting bogged down by documentation and user statements. Test engineers are looking for an off-the-shelf solution with a low lead time for their functional tests.”

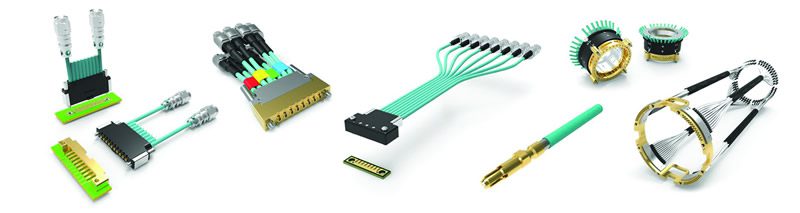

CarlisleIT’s CoreHC Ganged RF Interconnect system offers flexibility to designers of test fixtures, lowering costs of multiple RF channels through its boards. This high-performance multi-port RF solution centers around a compression force technology with stable and solderless results through 65GHz.

Becerra says that testing doesn’t represent a market; instead, it’s an extension of every market. Customers test to support product development, validation, or production. Test products ranging from probes and sockets to interconnects and oscilloscopes are used in test fixtures, and the demands placed upon the test equipment mirror those the end product will face in the field.

“That equipment might be a development kit to enable FPGA programming, a wafer level test in a semiconductor fab, a test fixture for production-level tests, or an electrical test lab where they’re testing some kind of chip or signal from a chip — it’s truly customer- and application-dependent,” he said.

“In one example, a data center customer is making what’s called the protocol analyzer, and we’re doing all the interconnect inside their box and outside their box, the cables that you never see, and the cables that are touched by customers, for every test. We also have chip manufacturer design houses, semiconductor manufacturers, and fabs that conduct package-level testing, which means testing the chip through the later stages of its life. We are in the test equipment for consumer electronics companies as well.”

CarlisleIT’s precision RF PCB connectors are available in various configurations and mating interfaces for design flexibility. (Left) 3.5, 2.92, 2.4, and 1.85 mm Solder-Mount Solutions (Right) 3.5, 2.92, 1.85, 1.35, 1.00 mm Solderless/Field-Replaceable Solutions

Chip-level testing, in particular high frequency (40 gigahertz and above) is becoming a significant area for CarlisleIT’s test products as applications move into the higher speeds and performance levels required by technologies such as 5G, AI, IoT, and automation. The speed of chips, different kinds of PCB structures, such as system-on-a-chip (SOC) configurations, miniaturization, and the increasing numbers of chips in use for more applications has led to a need for more sophisticated products for testing. “Any industry developing, programming, or integrating computer chips has a need for Test & Measurement,” said Becerra, adding that the main areas for test products fall into three main categories:

Automated Test Equipment (ATE): Applications around high-volume product testing requiring highly customized and dense packages, usually around semiconductor or consumer electronics tested at different stages. This includes development, characterization, and evaluation opportunities and highly specialized performance for go/no-go style tests.

Datacenter/Telecom: Applications around data transmission: Optical transmission, PCIe data transfer, and testing systems for other data transmission protocols.

General Purpose Test: Engineering applications in a test lab environment (can be for ad hoc or structured test plans), usually development or supporting development in other industries. Low-volume opportunities where more standard products must apply. More generalized performance for more “absolute” style tests.

“ATE and General-Purpose tests may have a lot of product overlap, but product requirements and follow on design are a lot different for automated opportunities for high-volume test,” Becerra said. “All industries have testing requirements, and if there is a chip or an antenna as part of the system, we are seeing more and more demand for RF ‘high-frequency’ testing. The different types of testing our customers are doing change the type of product they need.”

Common examples of those tests include:

Theoretical: Supporting next-generation design.

Development: Supporting product design.

Characterization: Supporting product design. Testing under real world conditions and performance requirements to help aid product design decisions. May be a part of qualification or production test in some capacity.

Qualification: Validating performance versus all requirements to qualify product for production.

Production Stages: Pass/fail testing for ultimate product acceptance. This is a broad term and encompasses “product” down to semiconductor wafers through complex sub-assemblies in a phone, to full system-level test for test equipment.

“There’s a whole world of testing just to get that phone in your hand put together,” said Becerra. “Every component level, from chip up to board level, with integrated antennas and our other RF componentry talking to that chip, and then that sub assembly — let’s call it the main board — are all tested to make sure the phone is going to work.”

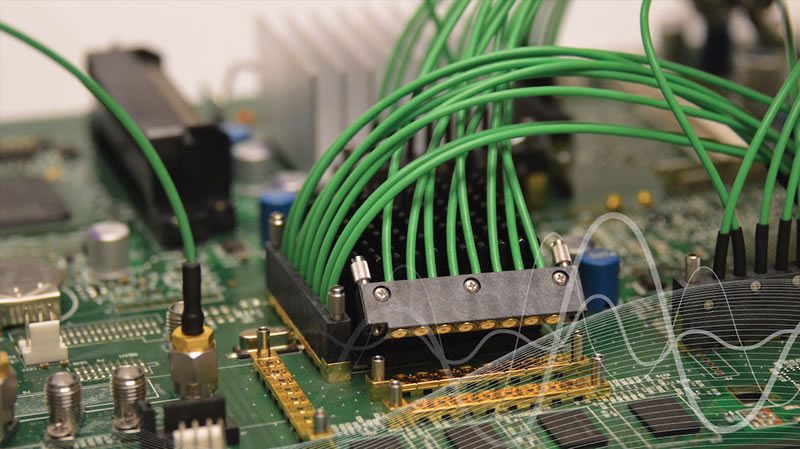

Samtec’s Bulleye test point cable system is another product that has been developed for test applications. This high-performance test assembly features a high-density space saving design that enables smaller evaluation boards and shorter trace lengths in test and measurement applications.

Samtec’s Bulls Eye® block compression mounts to the board for placement directly adjacent to the SerDes being characterized. The solderless design improves overall cost and is easy to use within a lab setting. End 2 of the cable assembly connects to instrumentation using any of the following connector options: 1.00 mm, 1.85 mm, 2.40 mm, or 2.92 mm.

Samtec’s Bulls Eye® block compression mounts to the board for placement directly adjacent to the SerDes being characterized. The solderless design improves overall cost and is easy to use within a lab setting. End 2 of the cable assembly connects to instrumentation using any of the following connector options: 1.00 mm, 1.85 mm, 2.40 mm, or 2.92 mm.

“Samtec’s Bulls Eye assembly has been a proven test and measurement solution for over a decade,” said Danny Boesing, Samtec’s product marketing manager. “During this time, the need for multi-channel high speed compression mount connectors with superior signal integrity has steadily increased. As a result, Bulls Eye assembly has also been adopted for use in clock/data recovery (CDR) for communications, millimeter wave radar systems, automated test equipment, next generation FR2 5G networks, and a variety of custom high-density high-performance designs.”

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for CarlisleIT and Samtec Inc.

Like this article? Check out our other Manufacturing and Test Equipment articles, our Special Topics Page, and our 2023 and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024