Cable Connector Seals May Determine the Life of Your Systems

Water is the enemy of electronics. Yet equipment ranging from our pocket-dwelling consumer devices to complex military gear has the potential for exposure to moisture. Good seals on cables and connectors can keep it out.

Dana Stoica, Global Marketing Manager, ODU-USA, Inc.

Hostile environments often expose the weakest parts of electronic systems, and these frequently turn out to be the points at which external entities, like cables, connect to a system. This article will examine the environmental challenges that cable connector manufacturers must address — placing specific focus on connectors’ ability to seal out dust, dirt, and water — as well as some of the variety of standards with which they may need to comply.

Environmental Challenges

Electronic systems and devices are present in every aspect of our lives, both at home and at work, and we expect them to operate reliably in a variety of conditions, depending on their intended purpose. The typical operating environment for consumer electronics, for example, is a lot less challenging than that encountered in military or industrial settings. Not every type of equipment needs to meet the most rigorous standards discussed here, but it’s critical to understand these standards and the requirements that they impose on equipment designed for diverse applications.

When reliability is paramount, cable connectors are often the most significant points of failure, particularly when used over prolonged periods of time. Such single points of failure are unacceptable under the extreme conditions in which military operations often take place. Consider, for example, the requirements imposed on diving equipment that must operate reliably at a depth of 20 meters. At that depth, the ambient pressure is three times greater than the atmospheric pressure at sea level. This means that submersible equipment, and in particular the seals that give such products their watertight properties, must be designed to withstand much greater pressure over prolonged periods than land-based systems.

Immersion in water is one of the many challenges faced by product developers. Others include exposure to dirt and dust, high humidity, extreme temperatures, caustic gases, corrosive liquids, shock and vibration, electrical breakdown, electromagnetic interference, and RF emissions.

The diversity of this list suggests that numerous standards may be relevant when evaluating the quality of cable connectors, and that is indeed the case. However, for the sake of depth versus breadth, this article will specifically focus on connector characteristics that seal it from the damaging effects of dirt, dust, and water, and are governed by industry standards including:

- IP rating – International Protection rating, also referred to as Ingress Protection

- NEMA – National Electrical Manufacturers Association

- MIL-STD-810G – U.S. Department of Defense, standards document

- MIL-DTL-38999 – U.S. Department of Defense, detailed specification

Common Sealing Terminology Mistakes

Perhaps the most commonly misused sealing term is “hermetic seal.” Its correct definition is a seal that is airtight to a specific leak rate as measured by a tracer gas (typically helium, per the EIA-364-02 standard test procedure) to a stated pressure differential. All too often, however, the term is mistakenly used in reference to water tightness, submersibility, chemical infiltration, or other properties not necessarily associated with pressure differentials. Test engineers must be very specific in describing the sealing characteristics they are measuring, because they may be entirely different from those covered by the term “hermetic.”

A seal that is either waterproof or water-resistant does not need to be hermetic as well. This is because molecules of water are substantially larger than the molecules of the gases that make up air, and thus simply cannot pass through the smaller gaps that would allow the passage of gas molecules.

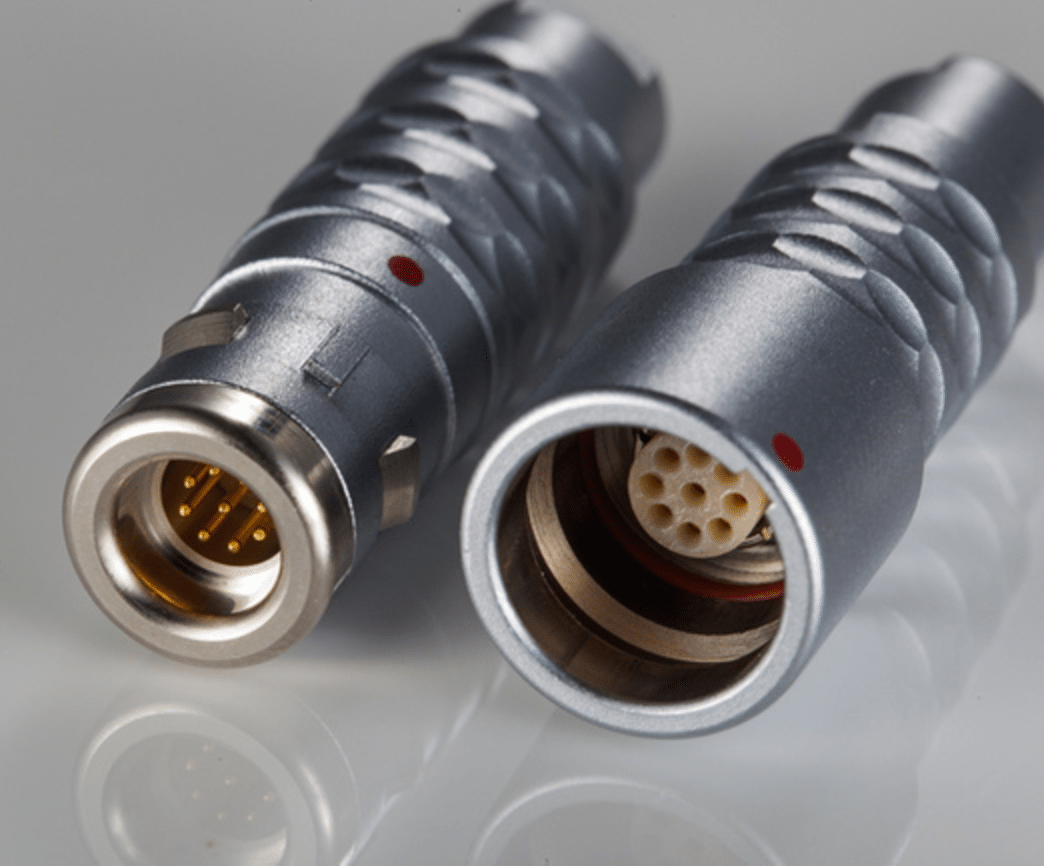

Figure 1: ODU’s AMC Series connectors feature a combination of O-rings, potting, and overmolding to achieve IP68-rated sealing performance.

Connector Sealing Standards and Technologies

The ODU AMC® connectors pictured in Figure 1 employ several technologies designed to ensure a watertight seal when the sockets are mated with their receptacles, and can be used to provide an in-line connection between two cables or to attach a cable to a device via a surface-mounted receptacle on the device enclosure. In both cases, a combination of O-rings, potting, and overmolding provide a robust seal that meets the IP68 specification, which guarantees total protection from dust ingress and protection from long-term immersion up to a specified pressure. ODU MINI-SNAP connectors (pictured in Figure 2) also comply with the IP68 specification, and achieve that rating through a combination of O-rings, elastic sealing, grouting, and encapsulation in a tight-fitting cable sleeve.

To provide harsh environment application customers with additional protective performance guarantees, some connector manufacturers develop products that adhere to even more stringent standards than are required. For example, all of ODU waterproof products are capable of immersion at a depth of two meters for at least 24 hours in accordance with the IEC 60529:2013 standard, which exceeds the IP68 specification. Several connector manufacturers, ODU included, also offer harsh environment connectors rated to the more rigorous IP69 specification, which guarantees total protection from dust ingress and the ability to withstand high-pressure steam cleaning.

Figure 2: ODU’s MINI-SNAP connectors achieve IP68-rated protection with a combination of O-rings, elastic sealing, grouting, and encapsulation in a tight-fitting cable sleeve.

Every Single Point of Failure is Vital

When selecting electronic components for use in harsh environment applications, it is important to consider every point at which leakage could occur. These generally turn out to be the points at which external entities, like cables, connect to a system. As such, the seals that protect cable connectors from dirt, dust, and water ingress tend to be of particular importance. To protect electronics from harsh environments, designers should ensure that both attached cables and the entire equipment enclosure adhere to common sealing requirements specified by IP ratings, NEMA, MIL-STD-810G, and/or MIL-DTL-38999. By identifying and understanding the subset of standards relevant to a particular harsh environment application, engineers can make more informed decisions throughout the equipment evaluation and selection process.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation