Modern Military and Commercial Aerospace Connectors Break Barriers to Enhanced System Performance

When connector performance is ideally matched to application requirements, modern military and commercial aerospace connectors can break barriers to enhanced performance in critical systems

John Whittaker, Product Development Manager, Amphenol Pcd

In today’s military and commercial aerospace world, engineers are challenged to incorporate more functionality in less space without increasing weight or sacrificing performance, payload, or range. Whether it’s increasing the capability of a guidance system, improving the functionality of an avionics sensor, or adding local intelligence to a remote system or subsystem, wired interconnects continue to play a key role, but finding a connector with the right combination of performance, size, and weight can be a daunting task.

In today’s military and commercial aerospace world, engineers are challenged to incorporate more functionality in less space without increasing weight or sacrificing performance, payload, or range. Whether it’s increasing the capability of a guidance system, improving the functionality of an avionics sensor, or adding local intelligence to a remote system or subsystem, wired interconnects continue to play a key role, but finding a connector with the right combination of performance, size, and weight can be a daunting task.

There’s often temptation to fall back onto tried and true connectors that have worked in the past, for example1960s-era M38999 metal circular or M24308 D-subminiature connectors. While functional and proven, these tend to be overly complex with performance far in excess of many application requirements. This paper will look at how new plated, plastic connectors measure up to traditional metal connectors in a specific application context and how matching connector performance to application requirements helps engineers meet their performance envelope.

Defining the requirements is key to selecting the connector with the right stuff. Design engineers need to look at application-level requirements, as well as electrical requirements to accurately gauge what type of performance is required from the interconnect. For illustration purposes, a simplified and stylized example of a problem statement for a connector to support a sensor package for use in a light support aircraft or low-altitude UAV might read as follows:

Electrical Requirements

- 2 28VDC, 3A continuous with a 6MHz AC carrier on 20AWG wire, shielded

- 2 RS485 twisted-pair communications on 24AWG wire, unshielded

- 2 power returns with 20AWG wire, unshielded, MIL-spec style

- 4 active low digital control signals with 24AWG wire, unshielded, MIL-spec style

Application Requirements

- Wire harness will use a MIL-spec wire with a stainless steel braid for EMI protection.

- Used in an unpressurized, non-temperature controlled area of an airframe, but not directly exposed to the external environment.

- Operational altitude not to exceed 10–15k feet.

- Connection will be made and unmade infrequently for maintenance, test, and upgrades.

- The connector is routed through a roughly 1” diameter opening during installation.

- Minimize This is a low-altitude, long-endurance UAV or light aircraft, after all.

Breaking these down individually, the application demands a connector that can support:

- 6x 24AWG and 4x 20AWG MIL-spec contacts.

- Power lines will require shielding termination to protect the 6MHz carrier signal from stray noise. The 6MHz base frequencies and fundamentals mean shielding below 100MHz. Factoring in the possible data bandwidth, shield performance below 1GHz is of interest.

- Not being exposed to the outside world means little or no impact risk.

- Sealing will be required, as there could be condensation and possibly immersion. Exposure to flight-line chemicals and fuels is also possible.

- Since mating and unmating is infrequent, there’s no need to worry about high mating cycles; 100-200 cycles should be sufficient.

- Low-altitude use limits temperature range, so it probably won’t exceed -25°C to +125°

- Choose a 0.750” maximum diameter to comfortably fit through 1” hole.

- For shock and vibration considerations, let’s assume a light support aircraft means a restricted or utility-type aircraft (e.g., crop duster) at 12,500lbs, with takeoff and landing speeds in the 60–100 mph range. Shock should not exceed 100g, and vibration should be minimal, say 15g sinusoidal.

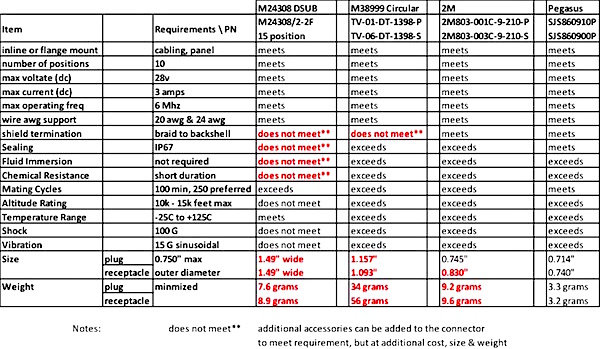

Based on these considerations, the following compares key specifications for several popular military and commercial aerospace connectors, including: legacy M24308 D-subminiature, M38999 circular connector, Amphenol Aerospace’s more modern 2M Series circular connector, and a connector typical of plated plastic connectors, Amphenol Pcd’s Pegasus Series. Table 1 lists the application requirements above and whether these connectors meet, don’t meet, or exceed the requirements. For selection purposes, this could be converted to a weight selection matrix.

Table 1: Connector Comparison

As seen in Table 1, the legacy D-sub easily meets the electrical specifications, but it does not meet the environmental specifications, size, or weight requirements. The M38999 easily meets or exceeds all of the requirements except for the braid termination, size, and weight, and adding a backshell to address the braid termination would further compound the size and weight penalty.

This makes perfect sense considering that the D-sub was conceived as a general-purpose, non-environmentally sensitive connector, and the M38999 as a general-purpose connector for rugged and harsh environments. Since neither the D-sub nor the M38999 were designed with a specific task in mind, they are either generally either over- or under-designed for the task at hand. In fact, both the D and M38999 were designed before “SWAP” and “lightweight” even became catchwords. Hence, although they can both be made to work in many applications, they’re often not the ideal choice.

The newer 2M and Pegasus connectors fared much better. The 2M was designed to address the size and weight issues inherent in the M38999, and is both smaller and much lighter. However, it still suffers from being general-purpose in that it was designed to cover a wide range of applications, and not specifically aerospace. So, though the 2M meets or exceeds all of the electrical and mechanical criteria, it still comes with a weight penalty relative to the plastic Pegasus connectors.

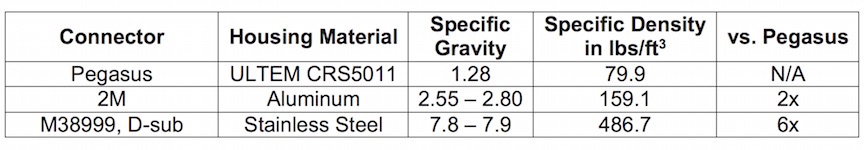

The Pegasus Series proves to be a much better choice for this application. Purposefully designed for commercial and military aerospace and avionics applications, this series meets all of the environmental requirements as-is. It’s environmentally sealed, unlike the D-sub, and has the temperature, chemical, and shock and vibration performance of the M38999, but with an integrated braid termination area. It’s also a fraction of the size and weight of both the D-sub and M38999, and is even smaller and lighter than the 2M due to a simpler design architecture and being completely made of plastic, which has a lower specific density.

Table 2: Weight comparison of ULTEM plastic to stainless steel and aluminum

Of course, there are limitations to plastic connectors. Plastic connectors may not be a good choice for applications in which direct impacts from tools, soldiers’ boots, and loose equipment or debris are common. Use in applications with very high mating cycles, such as radio headsets, video, network, and power, may also not be appropriate, as the plastic will wear faster than metal.

However, the avionic sensor application described here provides an excellent example of the type of application that can benefit from a lightweight, high-performance, EMI-shielded, plastic connector, such as Pegasus. Similar applications include: power and signal distribution for UAV electric fan motor power; cabin monitor and surveillance camera systems; door and flap motor actuators and controls; tail, wing, and warning lights; and wheel-well, cargo, and cabin lights. These applications require moderate pin counts, are disconnected infrequently for scheduled maintenance and protected from direct impacts, and demand the higher shock, vibration, temperature, and EMI shielding typically addressed by metal connectors.

Figure 1: Amphenol Pcd’s rugged Pegasus Series connectors

When evaluating connectors, it’s important to consider all of your options before falling back on the tried and true. Although M24308D-sub and 1960s-era M38999 metal circular connectors are functional, proven, and can be made to work in many applications, modern, lightweight, high-performance, EMI-shielded plastic connectors like Amphenol Pcd’s Pegasus Series provide more ideal solutions for many of today’s aerospace applications.