Connector Materials for Extreme Conditions

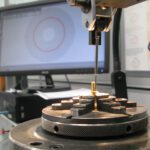

When failure is especially costly, operations demand high reliability. Designers, engineers, and suppliers are always on the search for materials that perform well under extreme conditions. Many applications subject connectors to very high pressures and high temperatures while requiring them to maintain functionality and performance for extended periods of time. When failure is especially costly,Read More