Connector Speeds Ramp Up in Rugged Embedded Computing Applications

By Bob Hult, Bishop & Associates

October 2012

Embedded computers are the brains behind a host of consumer, commercial, military, and avionic devices. From the Simon electronic toy introduced in the late 1970s to today’s advanced communication satellites, embedded computers pervade the products we use every day.

Embedded computers are the brains behind a host of consumer, commercial, military, and avionic devices. From the Simon electronic toy introduced in the late 1970s to today’s advanced communication satellites, embedded computers pervade the products we use every day.

Rather than design a special-purpose computer from scratch, embedded computers enable product engineers to access a universe of off-the-shelf modules to create unique computing devices quickly and economically. Standardized connectors defined by a standard insure plug compatibility. Embedded computers are available in multiple architectures, including single board computers, traditional backplane assemblies, stacking boards, and computer-on-module (COM), where a stackable module provides the base computing unit for a carrier board that adds custom features.

Unlike a personal computer, which is designed to perform a wide range of tasks, embedded computers are focused on a single function and integrated into a larger machine or system. They are often required to provide instantaneous response to changes as defined by their software. This “real time” computing characteristic is critical when embedded in applications that range from industrial control to military radar. One of the advantages offered by embedded computers is flexibility to adapt to advances in processor technology. The FMC form factor, for instance, allows OEMs to differentiate their products by taking advantage of low-cost FPGA devices mounted on a pluggable module. Many embedded computers are protocol agnostic, adding to their design flexibility.

Embedded computing systems tend to fall into three general application categories—commodity, mid-range and extreme high performance.

Each higher level is typically characterized by a significant increase in performance, environmental resistance, reliability, and price. Production volumes decrease as you move higher in the pyramid.

Each higher level is typically characterized by a significant increase in performance, environmental resistance, reliability, and price. Production volumes decrease as you move higher in the pyramid.

Embedded computers in the commodity segment are found in a wide variety of applications, including machine automation, process management, robotic systems, telecommunications, transportation control, and infotainment, although some COTS (commercial-off-the-shelf) units are utilized in avionic equipment. Many board manufacturers offer plug-compatible processor, I/O, and special purpose modules in each of multiple form factors. Availability of COTS base and option boards has enabled the embedded computing market segment to grow dramatically.

Applications for mid-range embedded computers exist in medical imaging, communication switching, factory automation, energy management, oil and gas exploration, and avionics. These are typically packaged as larger high-performance/reliability daughtercards plugging into standard defined backplanes.

High-performance embedded computers are found in advanced mission-critical, field-deployed military radar, weapons management, supercomputing, and aerospace equipment where absolute reliability in extremely harsh environments is required. Many of these daughtercards are application-specific and may incorporate proprietary hardware and software.

The connectors defined by a standard vary at each level of the application pyramid and reflect increasing performance and reliability demands. The boundary between the three tiers is not fixed, as an upward migration of commodity and mid-range embedded computers is being driven by lower cost and improved performance.

The venerable PC/104 format continues to dominate the commodity segment as its performance is updated in the PCIe/104 standard. Demand for higher packaging density and performance has resulted in a host of new form factors, such as EPIC, EBX, ETX, COMIT, SUMIT, COM Express, Core Express, ATX, Mini-ITX, Pico-ITXe, XTX, EMX, and Qseven, most of which have been introduced over the past 10 years.

The introduction of so many new form factors that feature incremental differences has resulted in a highly fragmented market and some degree of confusion among engineers. Form factors designed to support specific applications, such as the PXI platform, which is PCIe-adapted to test instrumentation equipment, have further expanded the mix of options.

The introduction of so many new form factors that feature incremental differences has resulted in a highly fragmented market and some degree of confusion among engineers. Form factors designed to support specific applications, such as the PXI platform, which is PCIe-adapted to test instrumentation equipment, have further expanded the mix of options.

In addition to the stacking connector, many embedded computer boards are studded with standard I/O connectors, including USB, D-subs, RJ45, Din audio, and power interfaces. On-board connectors may include PCIe, memory, and processor sockets.

Since many commodity embedded modules are often located within a larger system, they are generally protected from hostile environments. Stacking interfaces defined in recently introduced commodity embedded computer boards tend to feature increased bandwidth and greater packaging density using lower cost connectors. Samtec, a connector manufacturer that has built much of its product portfolio around mezzanine connectors, has been particularly successful in having several of its connectors defined in multiple embedded computer standards.

Historically, change has come relatively slowly to the embedded computing segment. This may be due to the fact that embedded computers are often expected to perform flawlessly for many years with little or no maintenance. Designers of embedded

computer boards take a very conservative approach to both hardware and software design to insure long term reliability. Adoption of new hardware and operating systems comes only after extensive test and verification. The explosion of new applications at all three levels of embedded computing is changing that paradigm.

Mobile consumer devices, including smart phones and tablet computers, are driving demand for systems that feature reduced power consumption, making Atom processors and ARM technology a high priority. At the other end of the spectrum are advanced military radar capable of not only detecting and tracking fast- moving targets but also identifying the specific type of aircraft. Increased automation control, including the burgeoning market for robots of all types and unmanned autonomous, aerial, land, and undersea vehicles, are opening new market potential for embedded computers.

Mid-range embedded computers have been dominated by architectures such as VME and CompactPCI. These traditional card cage systems are populated by 3U and 6U daughtercards that offer long-term reliability in performing complex tasks. Rack-mounted metal enclosures typically include the power supply, fan tray, guidance, and latching features for multiple daughtercards, as well as provide isolation from EMI. Systems designed around the VME standard use specific configurations of DIN 41612 backplane connectors based on 2.54 mm centerlines.

CompactPCI adopted a 2mm HM-type interface. A wide variety of connector manufacturers offer connectors that are certified to meet these specifications.

The top tier of the embedded computing market is currently dominated by standards established by the VITA Standards Organization (VSO). A continuing series of open standards define the architecture of real-time modular embedded computing systems that are utilized in the most demanding applications. These products feature extended bandwidth, low latency, performance scalability, mechanical durability, and environmental resistance, and are deployed in the most demanding applications. Their design is dictated by the key issues of size, weight, and power (SWaP).

Standards approved or in development include:

- ANSI/VITA 1.0, which is the base specification for VME 64-based systems. Expanded DIN 41612 connectors are defined, but ruggedized plug-compatible versions are available from several suppliers.

- ANSI/VITA 41, VXS backplane. Uses the MultiGIG RT2 connector from TE Connectivity.

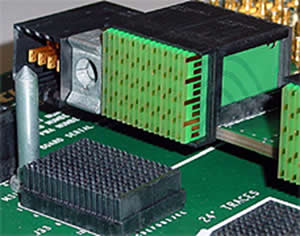

- ANSI/VITA 42, XMC mezzanine card. Uses the Samtec SamArray® connector. The ruggedized and high-speed VITA 61 XMC standard defines the TE Connectivity Mezalok stacking connector.

- ANSI/VITA 46, VPX, Next generation VME. Uses the TE Connectivity MultiGIG RT2 backplane connector. Connectors such as the KVPX® Series connectors from Hypertronics are considered a drop-in alternative.

- ANSI/VITA 57, FMC mezzanine card. Uses the Samtec SEARAY™ connector.

- ANSI-VITA 59 RSE Rugged System-On-Module Express uses the Samtec Q Strip® connector.

- ANSI/VITA 65, Open VPX. Latest iteration backplane system. Defines the MultiGIG RT2 backplane connector, but the VIPER® connector from Amphenol Backplane Systems is an alternative.

- ANSI / VITA 74 Nano-ATR uses the Samtec SEARAY right-angle connector.

The connectors used in these top tier applications are designed to support 10+ Gb/s bandwidth, and are offered in standard 3U and 6U configurations. The MultiGIG RT 2 connector features a unique “pinless” PCB edge contact design that can survive extreme shock, vibration, and temperature extremes.

The connectors used in these top tier applications are designed to support 10+ Gb/s bandwidth, and are offered in standard 3U and 6U configurations. The MultiGIG RT 2 connector features a unique “pinless” PCB edge contact design that can survive extreme shock, vibration, and temperature extremes.

Interfaces defined at one level continue to migrate to higher levels. The Micro TCA architecture, for instance, is based on a 0.75mm centerline one-piece card edge connector that was originally developed for applications in the telecommunications market. System designers in select military applications find it to be a sufficiently rugged and lower-cost alternative to VPX.

In many ways, the architecture of embedded computing systems is at the leading edge of implementing change at both the software and hardware levels. Traditional Windows-based X-86 software is migrating to more open operating systems, including Android and Linux, while supporting multiple I/O protocols, including USB, SATA, RS-232, VGA, Ethernet, and PCIe. Many embedded computers now sport Atom processors to minimize power consumption. Single board computers that feature FPGA devices on the carrier board with customized I/O provided via FMC mezzanine cards provide extreme design flexibility with minimal circuit change. Availability of many competing form factors and off-the-shelf functional modules keeps prices down and allows close matching of the product to the specific requirements of the application. This level of flexibility opens the door to enabling system designers to become more of a system integrator, greatly reducing the new product design cycle. The acceptance of surface-mounted I/O and stacking connectors is demonstrating the production and performance advantages of surface-mount technology.

The market for embedded computers is expected to see continued growth over the coming years as more electronics continues to pervade the devices we use daily. The many stacking and backplane connectors defined by industry standards that feature greater signal integrity, smaller profiles, environmental resistance, and improved thermal management will share in this growth.

No part of this article may be used without the permission of Bishop & Associates Inc.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024