High-Tech Medical Connectivity Products Create Smart Solutions

Robots, Big Data, and other high-tech medical technologies will help lower error rates and set new quality standards as the next generation of medical devices integrates smaller, modular electronics into highly connected medical environments.

The medical technology sector is a booming industry marked by rapid change. Miniature dosing devices, surgical robots, and medical interventions controlled via a network of sensors, screens, and computers are just a few of the latest high-tech medical connectivity products that are changing the way medical care is delivered. Doctors, patients, and care providers all stand to benefit from these developments. A look into research and development labs shows five big trends currently impacting medical technology: Big Data, sensorization, miniaturization, medical robots, and automation. Modular connectors help make it all possible.

The potential posed by Big Data has electrified companies across many sectors. High-tech medical technology capable of processing large amounts of data opens up new possibilities for increasing diagnostics speed and providing precision care. Current procedures for diagnostic imaging, by means of a simple X-ray machine, computer tomography (CT), or magnetic resonance imaging (MRI), are time-consuming and prone to errors.

More Precise Diagnostics

Cross-referencing image findings with thousands of suitable patient data sets, diagnostic information, and therapy types using software can save a great deal of valuable time and has the potential to improve treatment success. For instance, it may allow for cancer foci in the body to be identified and treated at an earlier stage. While there is no intention for Big Data to replace medical doctors and their expertise, it can relieve doctors from time-consuming processes and reduce the probability of errors. Software that can align respective analyses is also in significant demand from health insurance companies.

Health care organizations are creating interfaces with external servers and data centers that enable medicine-related services and analyses to be carried out. The data and results must be secured in such a way that they can only be accessed by appropriate personnel. Special data protection concerns and the privacy rights of patients require a high level of responsibility and security when it comes to sensitive health data.

The connectors utilized in these high-tech medical systems must facilitate the fast and secure transmission of large amounts of data with the utmost reliability. In particular, connectors and plug-in modules that are regularly disconnected from the device for cleaning or service must provide the highest degree of dependability and robustness.

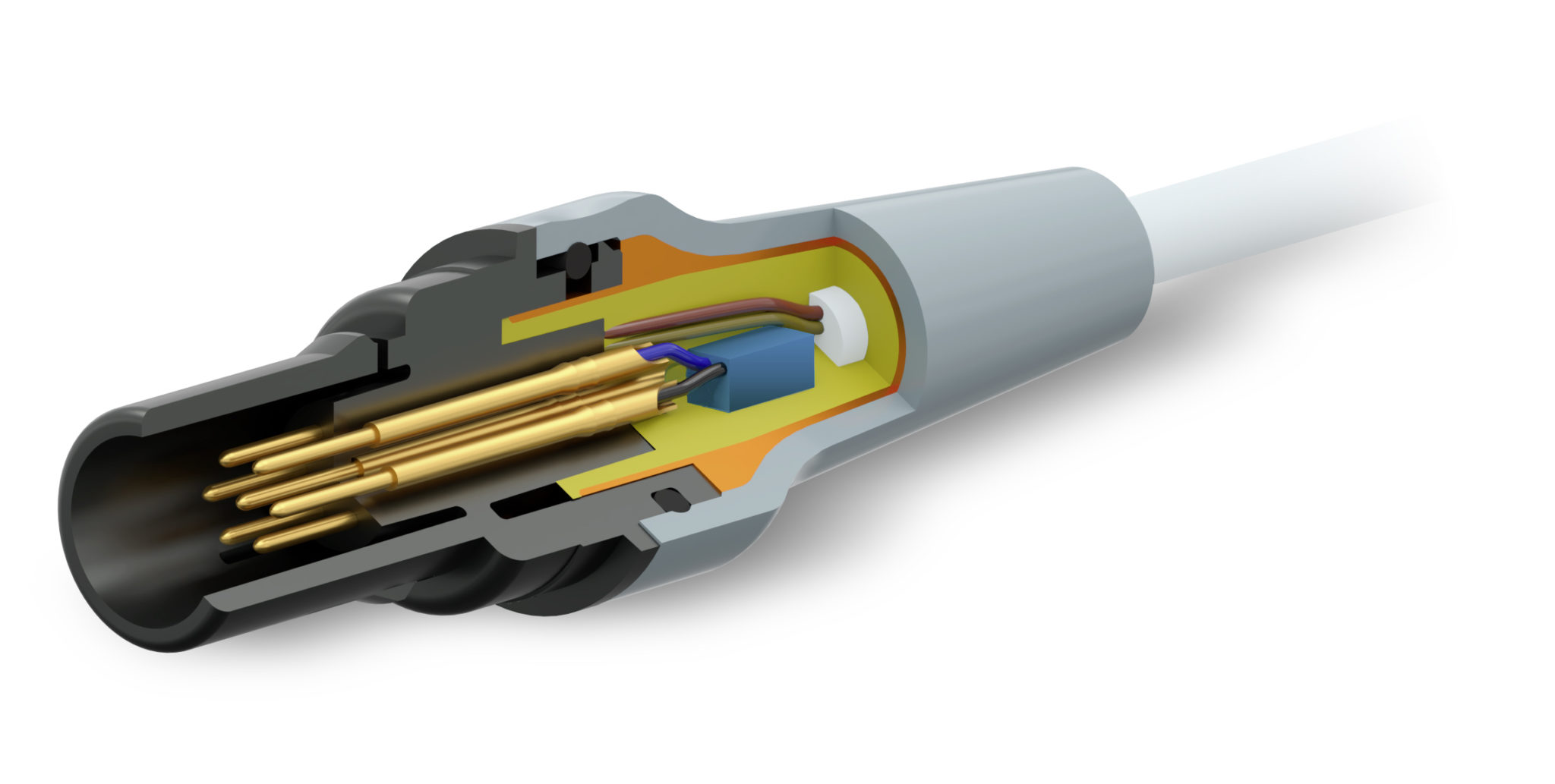

The need for dependability and robustness is all the more imperative when it comes to longevity. Connectors employed in high-tech medical technology must be able to handle a large number of mating cycles combined with high transmission quality, packing density, and vibration resistance. Application areas include, among others, connections to computer centers or internal video management systems in clinics that are used to analyze data from endoscopes, microscopes, CTs, and MRIs. For this purpose, time-tested circular connectors with push-pull locking mechanisms are a solid choice. When it comes to hybrid connectors that combine features such as fiber optics, power, signals, and other media, modular rectangular connectors are used.

ODU MAC-ZERO is a space-saving modular connector that is versatile, easy to clean, easy to handle, and can handle 60,000 mating cycles.

Sensor Technology Improves Patient Monitoring

Another important medical connectivity trend lies in the field of sensor technology. A growing number of sensors are used to monitor vital signs, lying positions, potential bedwetting, and other patient parameters and rely on highly reliable connectors to send the relevant information to the medical staff. For this reason, there’s a growing demand for sensor technology interfaces. In the auto industry, multiple sensors, along with several miles of cables, are built into cars to collect and analyze valuable data. In the medical field, one of the most widespread sensors is the SPO2, which is attached to the patient’s finger to measure the oxygen content in the patient’s blood. A newer, more high-tech medical technology, artificial respiration, is another important application area for sensor technology connectors, which are used to measure and monitor, among other things, the temperature and humidity in the breathing tube.

Device Recognition and Secondary Use Markets

Companies like ODU recognize that it is important to consider both single-use and secondary-use options, the trusted differentiation of which is made possible through the use of high-tech medical technology such as electrically erasable and programmable read-only memory (EEPROM) microchips integrated into connectors and cable assemblies. Using RFID or NFC technologies, EEPROM-enabled connectors and cable assemblies can provide precise device recognition and control through a special tracking system programmed with a predefined number of cycles or specific code. Once the predefined number of uses is exceeded, a warning sound beeps. In addition, EEPROMs also contain exact product and production key figures, which provides effective copy protection, prevents secondary use, and ensures that only the product only works with the specified manufacturer’s device.

EEPROM microchips are embedded into connectors.

Better Comfort Through Miniaturization

A third trend currently shaping medical technology is miniaturization. This plays an especially important role in devices that are being created in ever-smaller designs, often, at least in part, for greater patient comfort, and particularly in the areas of wearables and home care. A good example is hearing aids, the contacts and pins in which are responsible for transmitting sensor data and low battery voltage and thus need to provide maximum reliability and longevity. Miniaturization, combined with other challenging medical technology demands like reliability and longevity, places special production demands on manufacturers.

The ODU MEDI-SNAP Series features a highly secure plastic connector with a push-pull locking system, electromagnetic compatibility (EMC), and a user-friendly breakaway connector that’s ideal for use in high-tech medical technology.

Insulin injection devices for diabetes patients are another example. Today, these consist of small stickers attached to the body that dispense the right dose of insulin over the day through a mini cartridge. Such devices can be controlled via an app that tracks patient data and enables doctors to check whether the patient has administered the insulin and whether the dose is correct. This way, when body values change, medics can adjust the dose accordingly. Such devices may be the size of a matchbox with an integrated cannula and medication supply. As such, they require very tiny pins and contacts that possess specific properties regarding clearance and creepage distances, surface quality, and design.

Robots in the Operating Room

Another major trend is the use of automation and robotics in medicine. One of the best-known devices is the robot-assisted Da Vinci operating system, which is primarily used for minimally invasive surgery in the areas of urology and gynecology. With this technology, a surgeon does not have to be physically present at the operating table to participate in a procedure, but can control it remotely from in front of a monitor. It was originally developed in the 1990s to enable surgeons to carry out remote surgery in conflict areas.

The system is comprised of four remote-controlled arms that can assist the surgeon. Thanks to systems installed in the arms, operating instruments, endoscopes, light, or gas can be used simultaneously to expand the operating field. This way, surgeons can carry out procedures by themselves without needing additional assistants, which — especially in the face of increasing cost pressures — is a profound advantage. Furthermore, the use of robots in operations can minimize the risk of errors and improve the quality and safety of the intervention. In Israel, for instance, research is being carried out on the development of robotic systems to aid in complicated spinal surgery. In this particular field, the tiniest divergence or error can have grave consequences.

ODU’s new silicone-overmolded cable assemblies are especially designed to meet the stringent requirements and withstand the environmental and mechanical rigors of medical industry applications including endoscopy, monitoring, robotics, and dental equipment.

Computer-Controlled Knee Surgery

The networked operating room of the future will see robots collaborating with cameras and a navigation system that records all parameters and changes during an intervention. If the patient changes their position even minimally, for example, the system will register this immediately and adjust the device control in response. Currently, there’s a trend toward developing cheaper operation robots with just one or two arms for surgical instruments, and these are already used today in such areas as knee replacement surgery.

The interface between the robotic arm and the high-tech medical technology being used in a given surgery plays a central role in this field. These interfaces typically have a modular design in the form of a flange with various contacts to accommodate the transmission of various different media, including compressed air, fluids, power, and data streams.

New Interfaces Pose a Challenge to Manufacturers

This adjustment of robotic arms is currently posing a major challenge to all connector system manufacturers, but ODU has the benefit of already possessing a great deal of experience from the field of MRI. Such systems are also already being used in automotive production. However, in high-tech medical technology, the development is even more complex and requires increased customization due to the wide variety of products and particular sensitivity of the operating environment, with its especially high demands on safety and documentation. In addition, the lack of basic standards in this field has created further insecurity.

The direction being taken by the smart operating room trend is not quite clear yet. We are witnessing new developments in many areas and customized adjustment strategies seem to be emerging. Eventually, interfaces will have no exposed cables on the outside and cables and lines will be kept out of operating rooms as much as possible. Instead, devices and monitors will connect and latch onto a docking station or tower suspended from the ceiling, as special modular element components already exist for this purpose.

MEDI-SNAP circular connectors can be ordered in a variety of colors and coding options to ensure safety in the operating environment.

As automation continues to find a role in high-tech medicine, manufacturers of complex connector solutions are integrating new medical product regulations, such as the Medical Device Regulation (MDR), and labeling requirements, such as the Unique Device Identification (UDI), into their designs. Procut documentation, identification, and tracking are currently in great demand.

Due to the growing shortage of physicians, skilled personnel, and care staff, automated systems offer needed assistance in the operation room. They also offer expanded opportunities for remote operations via robots and joysticks, à la the Da Vinci system, which has been operating for years and allows, for instance, a specialist located in the US to carry out a complex intervention taking place in Germany. With the help of new high-tech medical technologies like these, more people will have access to high-quality medical treatments and achieve a better quality of life.

To learn more, visit ODU online.

Like this article? Check out our other New Technology, robotics, and sensors articles, our Medical Market Page, and our 2019 Article Archive.

- High-Tech Medical Connectivity Products Create Smart Solutions - December 3, 2019